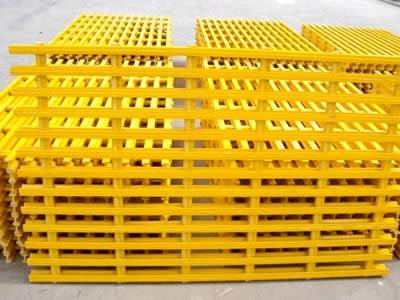

Pultruded Gratings for Platform, Deck, Stairs & Walkway

Pultruded fiberglass grating is made by the process of pultrusion, which pulls the glass strands through a machine and wraps in a glass fabric, then seals together with a resin. It is manufactured by assembling two structural fiberglass shapes (cross and bearing bars) into a grid pattern, which increases the support and stability of the grating under extreme loads.

With its much higher glass content, pultruded fiberglass grating has unidirectional strength, resulting in greater span capability than molded fiberglass grating. This makes it specified for applications that require larger spans or heavier loading.

Pultruded grating comes in many shapes and sizes to meet wide variety of applications. The standard shapes include:

- I-bar

I-bar allows more open space between the bearing bars, it is an industrial strength fiberglass grating, intended for applications with heavy loads and extreme conditions. - T-bar

T-bar provides more surface area, perfect for pedestrian applications. - Heavy load bar (Rectangular bar)

Heavy load bar is designed for extreme loads and the utmost of corrosive environments.

PFG-01: Pultruded fiberglass grating with corrugated surface.

PFG-02: Gray pultruded fiberglass gratings with gritted surface.

PFG-03: T bar style pultruded fiberglass grating for pedestrian applications.

PFG-04: Heavy load pultruded fiberglass grating for extreme loads.

PFG-05: Pultruded fiberglass grating with covered and gritted surface is suitable for special applications.

PFG-06: We offer wide range of pultruded fiberglass gratings, subject to order colours, surfaces or sizes.

Standard top surfaces

- Gritted surface.

- Smooth surface.

- Corrugated surface.

- Covered and gritted.

Key features

- Chemical resistance.

- High glass content for greater impact resistance.

- Corrosion resistance.

- UV protected.

- Lightweight yet durable.

- Fire retardant.

- Low thermal conductivity.

- Suitable for all environments, exterior or interior.

- Slip-resistance top surface.

- Easy fabrication and maintenance.

- Cost effective replacement for metal gratings.

- Extended life.

Specification

- Standard colour: yellow, light gray, dark gray, black. (Other colours like red or green is also available.)

- Resin: polyester resin, vinyl ester resin.

- Can be fixed to: steel, wood or concrete.

- Fixing method: a wide selection of grating clips.

PFG-07: I bar style dimension figure.

| Product code | Bar type | Open rate (%) | Thickness T (inch) | Top bar width A (inch) | Bar space B (inch) |

|---|---|---|---|---|---|

| PFG-I60100 | I | 60 | 1 | 0.6 | 1.5 |

| PFG-I50100 | I | 50 | 1 | 0.6 | 1.2 |

| PFG-I40100 | I | 40 | 1 | 0.6 | 1.0 |

| PFG-I60120 | I | 60 | 1.2 | 0.6 | 1.5 |

| PFG-I50120 | I | 50 | 1.2 | 0.6 | 1.2 |

| PFG-I40120 | I | 40 | 1.2 | 0.6 | 1.0 |

| PFG-I60125 | I | 60 | 1.25 | 0.6 | 1.5 |

| PFG-I50125 | I | 50 | 1.25 | 0.6 | 1.2 |

| PFG-I40125 | I | 40 | 1.25 | 0.6 | 1.0 |

| PFG-I60150 | I | 60 | 1.5 | 0.6 | 1.5 |

| PFG-I40150 | I | 40 | 1.5 | 0.6 | 1.0 |

| PFG-I60200 | I | 60 | 2 | 0.6 | 1.5 |

| PFG-I50200 | I | 50 | 2 | 0.6 | 1.2 |

| PFG-I40200 | I | 40 | 2 | 0.6 | 1.0 |

PFG-08: T bar style dimension figure.

| Product code | Bar type | Open rate (%) | Thickness T (inch) | Top bar width A (inch) | Bar space B (inch) |

|---|---|---|---|---|---|

| PFG-T38100 | T | 38 | 1 | 1.5 | 2.4 |

| PFG-T25100 | T | 25 | 1 | 1.5 | 2 |

| PFG-T18100 | T | 18 | 1 | 1.5 | 1.8 |

| PFG-T12100 | T | 12 | 1 | 1.5 | 1.7 |

| PFG-T38150 | T | 38 | 1.5 | 1.5 | 2.4 |

| PFG-T25150 | T | 25 | 1.5 | 1.5 | 2 |

| PFG-T12150 | T | 12 | 1.5 | 1.5 | 1.7 |

| PFG-T50200 | T | 50 | 2 | 1 | 2 |

| PFG-T33200 | T | 33 | 2 | 1 | 1.5 |

PFG-09: Heavy load bar style dimension figure.

| Product code | Bar type | Open rate (%) | Thickness T (inch) | Top bar width A (inch) | Clearance width C (inch) |

|---|---|---|---|---|---|

| PFG-HL60200 | Heavy load | 60 | 2 | 0.6 | 0.9 |

| PFG-HL50200 | 50 | 2 | 0.6 | 0.6 | |

| PFG-HL40200 | 40 | 2 | 0.6 | 0.4 |

PFG-10: The length of pultruded fiberglass grating is measured by the bearing bar.

| 3' × 8' | 4' × 8' | 5' × 8' |

| 3' × 10' | 4' × 10' | 5' × 10' |

| 3' × 12' | 4' × 12' | 5' × 12' |

| 3' × 20' | 4' × 20' | 5' × 20' |

| 3' × 24' | 4' × 24' | 5' × 24' |

Application

Pultruded fiberglass grating is designed and used in a wide variety of applications, especially in heavy traffic areas, such as walkways, platforms, swimming pool overflow, bridges, stair ramps, trench cover, manhole cover and commercial-grade catwalks.

Typical used fields

Marine, food & beverage, refining, chemical, water and wastewater treatment, pulp & paper.

PFG-11: FRP pultruded gratings applied as platform by the sea.

PFG-12: Walkways - pultruded fiberglass grating application.

PFG-13: Pultruded FRP grating works as safety landing in a manhole.

PFG-14: Pultruded fiberglass grating for marine application.

PFG-15: Pultruded fiberglass grating works as platform for the green belt.

PFG-16: Pultruded fiberglass grating can be used as trench cover.

PFG-17: Pultruded fiberglass grating as stair treads for entering cooling tower.

PFG-18: Pultruded fiberglass grating for safe footing in tunnel.

PFG-19: Pultruded fiberglass grating is perfect for working as drainage channel cover.

PFG-20: Pultruded FRP grating serves railway system.